$82

What:

Billet CNC cut hood hinge base upgrade (replaces old style welded sheet metal base).

Why:

In the early days, before I had my own CNC, having everything made from billet on a CNC mill was cost prohibitive in small quantities. Sheet metal was functional and cost effective, if not as slick looking. Now that I have my own CNC, I’ll do what I want! These machined bases are more rigid than the original welded bases, a little lower profile, and (IMHO), better looking. These reuse the upper portion of the old style hood hinge including the arms, as well as the 1/2″ shoulder screw and nylon washers.

All new hinges ordered after June 2020 come with the billet hinges by default.

Includes

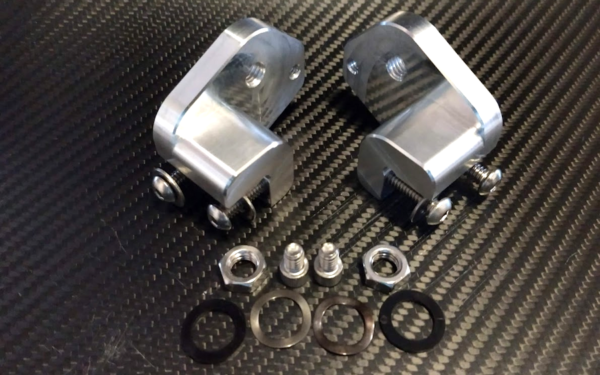

CNC cut billet bases

Stainless steel hardware

Steel wave washer for slight preload and better feel.

Installation:

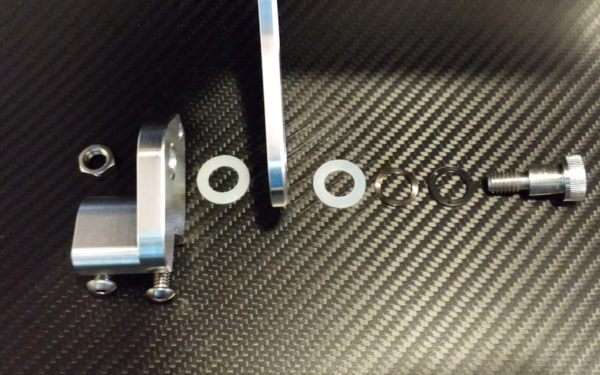

Unbolt the old bases and arms from the car. Remove the shoulder bolt, saving it and two white nylon washers per side. The nylock nut and small 1/4-20 socket head screw are not reused. Assemble the arm to the base in the following order: Shoulder screw, black plastic washer, steel wavy washer, white nylon washer, arm, white nylon washer, hinge base, jam nut. See photos for example layout. Drill two holes horizontally in the front subframe. It is easiest to place painters tape on the frame to make it easier to mark. Drill one hole per side, bolt on the base, and use the base as a guide to mark the second hole. I always recommend using a spot drill or center drill to start a hole. They wander less than a typical twist drill.